The J3 DentaJet is our entry-level PolyJet printer for small to medium-sized labs. It can produce mixed trays of three materials, including a large quantity of implant models, surgical guides, and gingiva masks, all on the same try and with unmatched accuracy.

Decrease Your Footprint and Increase Productivity

Small enough to fit in small and medium sized labs but designed with a larger print tray to create more parts in a compact, lab-friendly environment.

Simplify Production and Reduce Manual Labor

Unattended operation, fewer changeovers, less touch-time to load and minimal post-processing reduces manual labor while maximizing output.

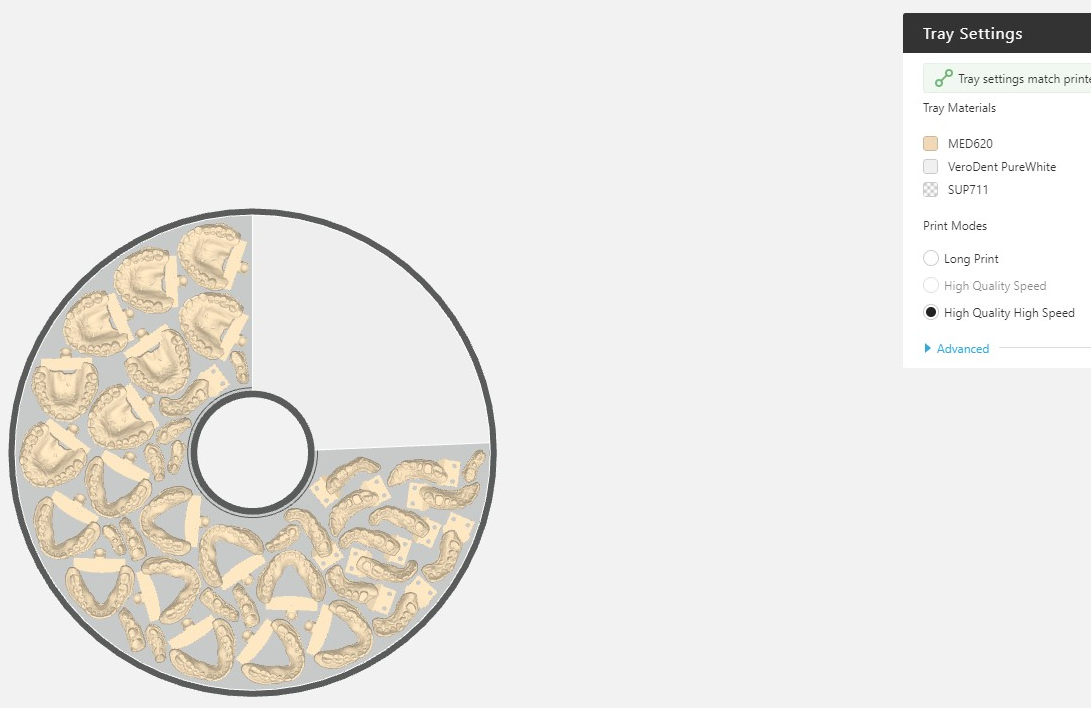

Reduce the Number of Printers You Need and Cut Costs with Mixed Trays

The J3 DentaJet™ is like having three printers in one. Use different materials in a single job. Print an implant case with a rigid opaque model together with a soft gingiva mask and a biocompatible transparent surgical guide, or print an RPD framework in a castable material together with the patient

model.

Unmatched Quality and Accuracy

The DentaJet is designed with a print tray to create more highly accurate parts from different materials — in a single print — without sacrificing patient-specific accuracy.

Print up to 37 Aligner Arches

in 3 hr 13 min

using HQHS

Print up to 17 RPD Cases

in 12 hr 29 min

using HQS mode

Print up to 64 Crown & Bridge Models

in 4 hr 24 min

using HQHS mode

Print up to 17 Implant Cases

in 12 hr 29 min

using HQS mode

Dental Applications

- Models: C&B, implant, orthodontic, removable, maxillofacial

- Surgical guides

- Gingiva masks

- Indirect bonding (IDB) trays

- RPD frameworks

- Custom impression trays

- Try-ins

Multi-Material Capabilities

Print up to 3 different resins in a single job, produce what you need when you need it.

Scale Production

Deliver on a wide array of cases with speed and efficiency maintaining high accuracy and quality.

Smart Workflow

Leverage GrabCAD to streamline production. Manage multiple Stratasys printers and individual print jobs.